Why Train in Aviation Maintenance Technology?

LOCATIONS OFFERED: TULSA AND BROOMFIELD (DENVER AREA)

What is Aviation Maintenance?

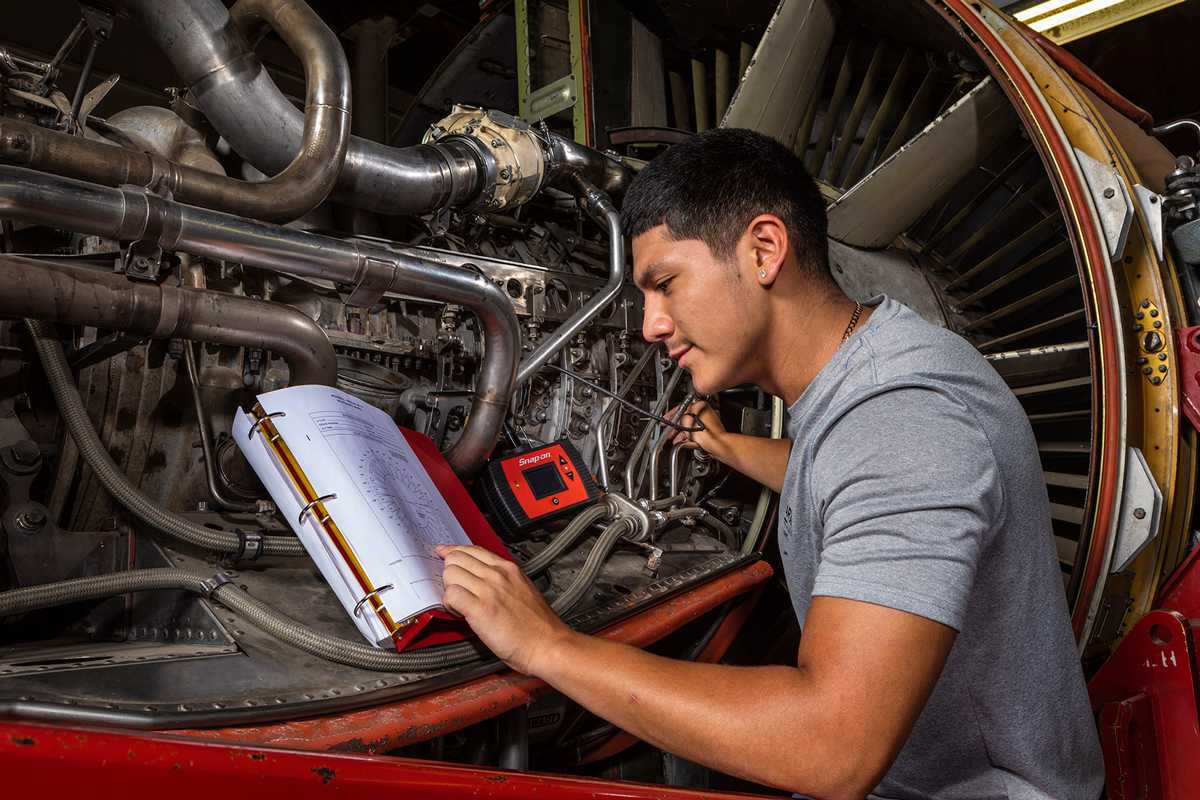

Aviation Maintenance Training at Spartan

Interested in Learning More?

Topics you’ll learn about include:

Aircraft Instrumentation, Communication and Navigation

Aircraft Flight Controls

Hydraulics and Landing Gear

Reciprocating Engine Systems

Turbine Engine Systems

Aircraft Electrical Systems

Aviation Maintenance Practices

Fuel Metering and Propellers

Part of the Demand for Airline Technicians

according to the Boeing Pilot Technician Outlook 2021 – 2040.

*Boeing: Pilot and Technician Outlook, http://www.boeing.com/commercial/market/pilot-technician-outlook/

Hear From Our Graduates

At Spartan’s April 2016 career fair, Joel was offered a position with Endeavor Air. Shortly after graduating; Joel garnered his A&P license and soon after that moved to Tennessee to start his career as an Aviation Maintenance Technician for Endeavor Air. Today, Joel also continues to serve his country as a member of the US Air Force Reserves.

Sample Aviation Maintenance Classes

For every hundred hours that an aircraft is used, the aircraft is required to be inspected based on standards established by the manufacturer and the FAA. Training in our program not only teaches the skills needed to become an aircraft technician, but it can also help you develop a versatile skill set that is utilized in other industries, such as automotive and diesel, heavy equipment, power and light, and industrial technology. Much like other programs at Spartan College, our AMT program provides a balance between the lab and lecture.

- ARF 2001 - Metallic Structures

- PPT 2005 - Turbine Engine Fundamentals

- GEN 1002 - Aviation Science

- PPT 2001 - Reciprocating Engines

- GEN 1003 - Aviation Maintenance Practices

For a Full List of Classes Choose a Campus